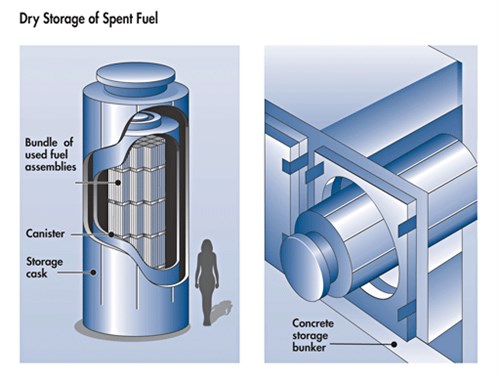

Dry cask storage allows spent fuel that has already been cooled

in the spent

fuel pool for at least one year to be surrounded by inert

gas inside a container called a cask. The casks are typically steel

cylinders that are either welded or bolted closed. The steel

cylinder provides a leak-tight confinement of the spent fuel. Each

cylinder is surrounded by additional steel, concrete, or other

material to provide radiation shielding to workers and members of

the public. Some of the cask designs can be used for both storage

and transportation.

There are various dry

storage cask system designs. With some designs, the steel

cylinders containing the fuel are placed vertically in a concrete

vault; other designs orient the cylinders horizontally. The

concrete vaults provide the radiation shielding. Other cask designs

orient the steel cylinder vertically on a concrete pad at a dry

cask storage site and use both metal and concrete outer cylinders

for radiation shielding. See the picture of a

typical dry cask storage system.

The first dry storage installation was licensed by the NRC in

1986 at the Surry Nuclear Power Plant in Virginia.

Spent fuel is currently stored in dry cask systems at a growing

number of power plant sites, and at an interim facility located at

the Idaho National Environmental and Engineering Laboratory near

Idaho Falls, Idaho. See the map showing the location

of existing independent spent fuel storage installations.

(Source: NRC)